Remember the times when warehouses used to be full of commotion and storage workers were rushing like ants in semi-organized chaos carrying boxes of goods from one corner to another?

Fast forward to today, and you’ll find the descendants of these warehouses have evolved into neatly operating smart facilities. This is all thanks to the magic of warehouse automation technology.

However, this transformation is not just about swapping humans for robots. It’s about making the warehouse more efficient and organized, increasing the accuracy of the operations to make people and machines work together, eventually creating a more effective supply chain.

Contents

What is Warehouse Automation?

At its core, warehouse automation involves the use of technology to perform tasks that were traditionally done manually.

Warehouse system automation is revolutionizing the way businesses handle their logistics and supply chain operations. By integrating advanced technologies, companies are achieving unprecedented levels of efficiency, accuracy, and productivity.

This includes everything from automating warehouse systems that streamline inventory management, to implementing goods-to-person technology that delivers items right to the worker’s station.

But there’s more to this transformation than just adopting new tools and software – it’s about reimagining the possibilities of what a modern warehouse can be.

Should You be Investing into Warehouse Automation Technology?

Even the most basic warehouse automation technology can be expensive. The purchase of an autonomous forklift and preparation of a suitable working environment in the warehouse costs much more than employing a forklift operator.

The upfront costs of implementing picking robots is similarly high. And this is just a foretaste of the enormous investment required to create a fully automated warehouse. In many cases, adapting existing buildings is not an option so they have to be built from scratch. Construction works, installing equipment and commissioning are not only a financial risk, but take a lot of time.

Do the arguments above suggest you should cancel all warehouse automation projects? On the contrary! Automated warehouses pay off quickly!

Expensive Automation, Cheap Operation

Warehouse automation solutions will help you significantly increase warehouse productivity and improve order fulfillment accuracy. And, of course, automating manual processes helps to reduce labor costs.

Technologies such as automated storage and retrieval systems, autonomous mobile robots, and warehouse management systems play a pivotal role in this transformation. These systems work together to create a seamless flow of goods through the warehouse, from receiving to shipping, ensuring that businesses can keep up with customer demands while maintaining high-quality standards.

The categories of warehouse automation range from basic mechanization to advanced systems that leverage artificial intelligence (AI) and machine learning (ML). Basic warehouse automation might include conveyor belts and simple machinery that assist with moving goods, whereas advanced automation incorporates sophisticated robots and software systems that can make decisions, adapt to changes, and perform complex tasks with minimal human intervention.

This spectrum of automation solutions means that businesses of all sizes and industries can find technologies that match their specific needs and challenges.

As we explore the world of warehouse automation, it’s clear that this is not just a trend but a fundamental shift in how supply chains operate. By embracing these technologies, companies can not only improve their current operations but also position themselves for future growth and success in an increasingly competitive marketplace.

Understanding Warehouse Automation

Let’s focus more on the different systems that make up warehouse automation and the innovative technologies driving advancements in the field.

Types of Warehouse Automation Systems

Warehouse automation encompasses a range of technologies designed to improve efficiency and accuracy in various warehouse operations. Let’s examine some of the key systems.

- Goods-to-Person (GTP) Technology: This system reduces the need for workers to move around the warehouse by bringing items directly to the picking station. It significantly cuts down on travel time and physical exertion, making the picking process faster and less labor-intensive.

- Automated Storage and Retrieval Systems (AS/RS): AS/RS are integral to modern warehouses, automatically placing and retrieving goods from storage locations. These systems are highly efficient for managing inventory, optimizing storage space, and improving order accuracy.

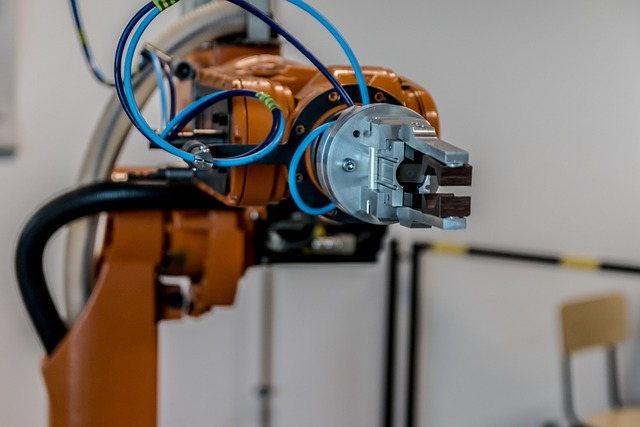

- Autonomous Mobile Robots (AMRs) and Automated Guided Vehicles (AGVs): AMRs and AGVs transport goods within the warehouse, following predefined paths or using sophisticated navigation technologies. They are essential for moving products efficiently from one location to another, reducing manual handling, and speeding up the fulfillment process.

Innovative Technologies in Warehouse Automation

The landscape of warehouse automation is continually evolving, with new technologies enhancing capabilities and offering novel solutions to traditional challenges.

- Artificial Intelligence (AI) and Machine Learning (ML): AI and ML algorithms analyze data to optimize warehouse operations, offering insights into demand forecasting, inventory management, and operational efficiencies. These technologies enable warehouses to adapt to changes in real-time, improving decision-making and operational agility.

- Internet of Things (IoT) and Smart Warehouses: IoT technology connects devices and systems throughout the warehouse, providing real-time data on inventory levels, equipment status, and environmental conditions. This interconnectedness facilitates better inventory management, equipment maintenance, and overall operational visibility.

- Virtual Reality (VR) and Augmented Reality (AR) for Training and Operations: VR and AR technologies are used for training staff and assisting with complex warehouse operations. By overlaying digital information onto the physical environment, these tools help improve accuracy, reduce errors, and enhance training effectiveness.

How to Implement Warehouse Automation Systems to Your Business?

Adopting warehouse automation technologies requires strategic planning and collaboration to ensure a smooth integration into existing operations. Consider the following 3 steps before you start the automation for your warehouse processes.

1. Strategic Planning

Understand your current processes, identify areas for improvement, and set clear objectives for automation. This step is critical for aligning automation efforts with overall business goals and ensuring a positive return on investment.

The process should start with mapping out every step of your warehouse operations, from receiving to shipping, and identifying bottlenecks or manual processes that could be streamlined with automation.

Setting clear, measurable objectives for what you want to achieve with automation (e.g. reducing order processing time, increasing inventory accuracy, decreasing labor costs) is crucial. These goals should directly support your broader business objectives, ensuring that your investment in automation yields tangible benefits.

Additionally, there will be growing need for a skilled workforce capable of managing and maintaining these systems. Investing in training and development is crucial for preparing employees for the future of work in automated environments.

Conducting a cost-benefit analysis as part of this phase can help justify the investment by projecting potential returns, such as reduced costs on manual labor, improved throughput, and reduced human error rates.

2. Collaboration with Stakeholders

Implementing warehouse automation is not solely a technical challenge. Engage with all relevant parties of this massive change.

This includes warehouse staff who will interact with the new systems, management who will oversee the transition, and technology providers whose solutions will drive the change. Engaging these groups early and often is key to identifying potential resistance, understanding concerns, and incorporating feedback into the implementation plan.

For example, regular meetings and workshops can help demystify the technology for staff, address fears about job displacement, and highlight the benefits automation brings to their roles.

Similarly, involving IT and operations management ensures that the selected technologies align with existing infrastructure and operational workflows. Effective stakeholder engagement fosters a sense of ownership and enthusiasm for the project, which is critical for smooth adoption and long-term success.

3. Selecting and Integrating a Warehouse Management System

A robust Warehouse Management System (WMS) is essential for managing your warehouse operations. It should integrate seamlessly with your automation technologies, providing a centralized platform for monitoring and controlling various aspects of warehouse operations.

A suitable Warehouse Management System acts as the brain of your automated operations, orchestrating movements, and processes across the warehouse space. When selecting a WMS, it’s important to look for a system that not only meets your current needs but is also scalable to accommodate future growth and technological advancements.

Additionally, consider advanced warehouse automation systems with features like real-time inventory tracking, data analytics, and reporting capabilities, as these will provide deeper insights into your operations and drive continuous improvement.

Integration testing and pilot runs are essential steps to ensure the WMS works harmoniously with your automation tools before full-scale deployment.

The Future of Warehouse Automation

As we step into the future of warehouse automation, it’s clear that the pace of innovation is not slowing down.

From the innovative 3DBinPacking technology that helps to optimize everything regarding the speed and efficiency of the packing process, all the way to the Boston Dynamics warehouse robots that look like a scene straight out of a Black Mirror episode, it really seems like the future is already here!

The potential for transforming logistics and supply chain operations through technology is vast, with new advancements continually emerging.

For example, check out the Digit humanoid robot that Amazon has just started using in its US warehouses as a good example of where we’re headed to already in a very recent future.

Trends Shaping the Future of Warehouse Automation

Several key trends are driving the evolution of warehouse automation, promising to bring even greater efficiency, flexibility, and intelligence to warehouse operations.:

- Blockchain Technology: Blockchain offers unmatched transparency and traceability in supply chain operations. By providing a secure and unchangeable record of transactions, blockchain technology helps track the movement and status of goods in real-time, enhancing the verification of product authenticity and reducing the risk of counterfeit goods.

- Virtual and Augmented Reality (VR/AR): These technologies are revolutionizing training and operational procedures in warehouses. VR creates immersive environments for training staff safely and effectively, while AR overlays digital information onto the physical world, guiding workers in complex tasks with improved accuracy and efficiency.

- Flexible Automation Solutions: The adoption of Autonomous Mobile Robots (AMRs) and collaborative robots (cobots) exemplifies the shift towards more adaptable and scalable automation solutions. These technologies can be seamlessly integrated into existing operations, allowing warehouses to respond swiftly to changing demands without significant overhauls.

- 5G Technology: The rollout of 5G networks is set to turbocharge warehouse automation systems, enabling faster, more reliable communication between devices and systems. This advancement will facilitate real-time data analysis and decision-making, further optimizing warehouse operations.

Conclusions

The future of warehouse automation is a dynamic and evolving landscape, shaped by technological advancements, sustainability considerations, and the continuous pursuit of operational excellence.

By staying informed about emerging trends, addressing potential challenges, and embracing sustainability, businesses can navigate the complexities of warehouse automation and harness its full potential for transformative growth and competitiveness in the logistics and supply chain sectors.

FAQs on Warehouse Automation

What is warehouse automation?

Warehouse automation refers to the use of technology and machinery to perform tasks traditionally done by human workers in a warehouse setting. This includes inventory management, material handling, and order fulfillment processes, all aimed at increasing efficiency, accuracy, and productivity.

What is the future of warehouse automation?

The future of automated warehouse processes is characterized by significant advancements in artificial intelligence (AI), Internet of Things (IoT), and robotics, driving efficiencies and smarter operations.

Enhanced real-time decision-making supported by 5G technology, alongside a heightened focus on sustainability, will transform logistics, ensuring warehouses are more responsive to market demands and environmental considerations.

How does 5G technology influence warehouse automation?

The advent of 5G technology promises to significantly enhance warehouse automation by providing faster, more reliable connectivity for automated systems and IoT devices.

This can enable more sophisticated, real-time decision-making processes, improve communication between devices, and facilitate the adoption of technologies that require high-bandwidth, low-latency connections.

Can small and medium-sized enterprises (SMEs) benefit from warehouse automation?

While the scale of implementation may differ, SMEs can significantly benefit from adopting warehouse automation technologies. Solutions like collaborative robots (cobots), pick to light systems, and cloud-based warehouse management systems can enhance productivity and efficiency, even within smaller operations.

The key is to identify specific areas of need and implement scalable, cost-effective solutions.